With the continuous development of the manufacturing industry, the requirements for product quality are increasing day by day. Online detection of film defects has become an indispensable part of modern production. As an important component of many electronic, optical and semiconductor products, the surface defects of thin films not only affect the performance of the products, but also may lead to serious quality accidents. Therefore, how to efficiently and accurately detect film defects during the production process has become the key for enterprises to enhance their competitiveness.

Against this backdrop, Thermo Fisher Vision has provided reliable quality control solutions for the industrial sector with its advanced online film defect detection technology. As a globally leading provider of optical imaging and inspection solutions, Thermo Fisher Vision, with its strong technical strength and rich industry experience, has successfully helped numerous enterprises achieve intelligent upgrades in their production processes.

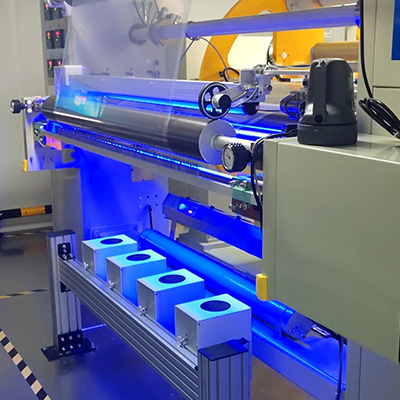

Thermo Fisher's online film defect detection system, which employs high-precision optical imaging technology, can capture in real time the minute defects on the film surface, such as cracks, particles, and bubbles. This system realizes the automatic identification and classification of defects through high-resolution image acquisition and analysis, combined with artificial intelligence algorithms. Compared with the traditional manual detection method, it not only improves the detection efficiency, but also significantly reduces human errors, ensuring the accuracy and consistency of the detection results.

In practical applications, Thermo Fisher's detection system can be seamlessly integrated with the production line, achieving full-process monitoring from raw materials to finished products. Through real-time data feedback, enterprises can promptly adjust production parameters and optimize process flows, thereby effectively controlling product quality. In addition, the system also supports a multi-level alarm mechanism. Once an anomaly is detected, it can immediately trigger a warning, helping enterprises respond quickly to problems and avoid potential quality risks.

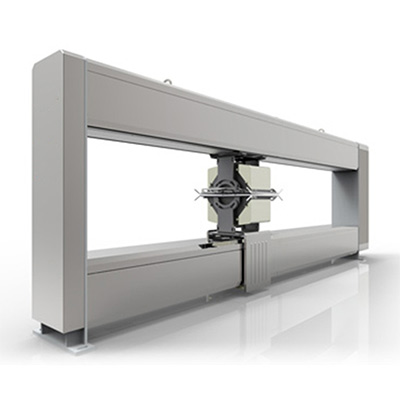

In addition, Thermo Fisher's detection technology also has good adaptability and is applicable to various types of film materials, including silicon-based, glass-based, polymer, etc. Whether it is high-purity semiconductor materials or complex-structured optical components, they can all be precisely detected through this system, meeting the demands of different industries.

In the industrial sector, Thermo Fisher's online film defect detection technology not only enhances production efficiency but also brings significant economic benefits to enterprises. Through intelligent and automated inspection processes, enterprises can reduce waste and increase the yield of qualified products, thus occupying a favorable position in the fierce market competition.

In conclusion, online detection of film defects is an indispensable part of modern manufacturing. Thermo Fisher Vision, with its advanced technology and comprehensive solutions, provides reliable quality assurance for the industry. With the continuous advancement of technology, it is believed that in the future, film detection technology will become more intelligent and accurate, providing stronger support for the high-quality development of the manufacturing industry.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down