In modern manufacturing and packaging industries, the quality of paper directly affects the appearance, functionality and user experience of products. Therefore, online detection of surface defects on paper is particularly important. Traditional detection methods often rely on manual visual inspection or simple equipment, which are inefficient and costly, and thus difficult to meet the demands of large-scale production. With the advancement of technology, SIMVision has launched a series of advanced online detection systems for paper surface defects, bringing brand-new solutions to the industry.

The Importance of Online detection of Paper surface defects

Surface defects of paper may include various problems such as scratches, stains, wrinkles, damages and bubbles. These defects not only affect the aesthetic appeal of the product, but may also reduce its service life and functionality. Therefore, an efficient online detection system can help manufacturers promptly identify and eliminate substandard products during the production process, thereby enhancing product quality and production efficiency.

SIMVision's innovative solutions

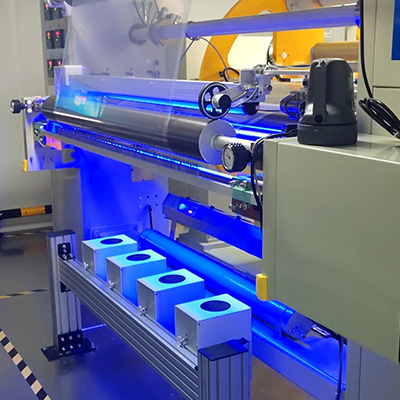

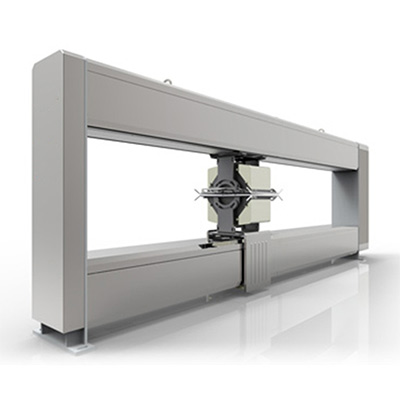

SIMVision is a high-tech enterprise specializing in industrial inspection and automation technology, dedicated to providing customers with high-precision and highly reliable inspection solutions. Its online detection system integrates image recognition, machine vision and artificial intelligence algorithms, capable of automatically identifying and classifying defects on the surface of paper, achieving rapid and accurate detection.

Advantages and features

High precision and high sensitivity: Through advanced image processing technology, Thermo Fisher's system can identify various minute defects, including those that are difficult to detect with the naked eye.

Real-time detection and feedback: The system can operate in real time on the production line, promptly feedback the detection results, and enhance the automation level of the production line.

Multi-defect identification and classification: Supports the identification and classification of multiple defect types, adapting to different paper materials and production requirements.

Customizable: The system can be customized according to the specific needs of customers to meet the testing requirements of different industries.

Data-driven decision-making: The system can generate inspection reports, providing data support for quality control and process optimization.

Application field

Thermo Fisher's online paper surface defect detection system is widely used in the following industries:

Packaging industry: Used for detecting surface defects of cartons and packaging materials.

Printing industry: It is used to detect the flatness and surface quality of printed paper.

Logistics and transportation: Used for detecting damaged paper during transportation.

Food and pharmaceutical industry: Used for inspecting the surface quality of packaging materials to ensure product safety.

With the continuous development of artificial intelligence and Internet of Things technologies, online detection of paper surface defects will also embrace more intelligent and automated development directions. Thermo Fisher Vision will continue to lead industry trends, providing customers with more efficient and intelligent inspection solutions, and helping enterprises achieve high-quality production and continuous innovation.

Key words: Online detection of paper surface defects, Thermo Fisher Vision, industrial inspection, machine vision, defect recognition, automated inspection, quality control, packaging industry, printing industry, intelligent inspection.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down