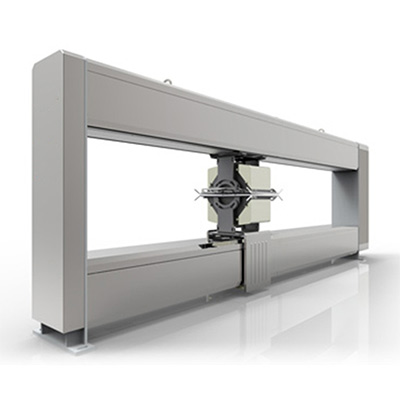

In modern manufacturing, precise film thickness control is critical for ensuring product quality and process efficiency. A film thickness gauge is a sophisticated instrument designed to measure the thickness of thin films, sheets, and coatings with high accuracy, catering to industries ranging from electronics and packaging to automotive and healthcare. This technology has evolved from manual calipers to advanced automated systems, integrating optical, ultrasonic, and electromagnetic principles to meet the demands of high-speed production lines.

Technological Principles and Innovations

Film thickness gauges employ diverse measurement techniques tailored to specific materials and applications:

Optical Measurement (Laser & Infrared)Laser interferometry and infrared spectroscopy enable non-contact, real-time thickness monitoring. Laser gauges emit a beam onto the film surface, calculating thickness by analyzing the reflection time or interference patterns. Infrared sensors, meanwhile, detect thickness based on light absorption through the film, ideal for transparent or semi-transparent materials like polymer films and optical coatings.

Ultrasonic TechnologyUltrasonic gauges use sound wave propagation to measure thickness. A transducer emits ultrasonic pulses that reflect off the film’s top and bottom surfaces; the time interval between reflections is converted into thickness data. This method suits multi-layer films and non-transparent materials, offering high precision even for complex structures.

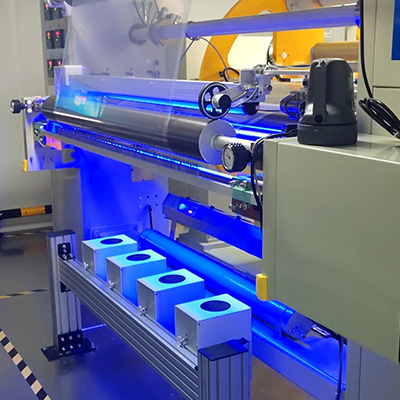

Electromagnetic and Capacitive SensingElectromagnetic gauges utilize eddy current or magnetic induction to measure conductive films, while capacitive sensors assess thickness by detecting changes in capacitance between two electrodes. These methods are valued for their speed and compatibility with online production lines.

Critical Applications Across Industries

Electronics ManufacturingIn semiconductor and display panel production, film thickness gauges ensure the uniformity of photoresists, dielectric layers, and protective coatings. For instance, in OLED display fabrication, nanometer-level thickness control of organic layers directly impacts screen brightness and lifespan.

Packaging and ConvertingFood packaging films require precise thickness to maintain barrier properties against moisture and oxygen. Gauges help optimize material usage, reducing waste while ensuring product shelf life. In flexible packaging, real-time thickness monitoring prevents issues like film breakage during high-speed printing.

Automotive and AerospaceThin films used in automotive coatings, fuel cells, and aerospace composites demand strict thickness control for durability and weight reduction. Ultrasonic gauges, for example, inspect the thickness of anti-corrosion coatings on aircraft components to ensure safety and longevity.

Medical DevicesMedical films for drug delivery systems, surgical membranes, and diagnostic sensors require micron-level precision. Optical gauges enable non-destructive testing, ensuring compliance with regulatory standards for biocompatibility and performance.

Advantages and Industry Impact

Quality AssurancePrecise thickness measurement minimizes defects like uneven stretching, curling, or performance inconsistencies, boosting product yield and reducing rework costs. A study in the packaging industry shows that automated thickness gauges can improve film uniformity by 95%, cutting material waste by 20%.

Process OptimizationOnline thickness gauges integrate with production lines, providing real-time feedback to adjust extrusion, coating, or calendering processes. This proactive control enhances efficiency, especially in high-volume manufacturing where even minor thickness variations accumulate into significant losses.

Data-Driven InsightsModern gauges often connect to industrial IoT systems, generating analytics on thickness trends, machine performance, and material consumption. These data support predictive maintenance and process refinement, aligning with Industry 4.0 initiatives.

Future Trends: Integration and Miniaturization

As Industry 4.0 progresses, film thickness gauges are evolving toward:

Multi-sensor Fusion: Combining optical, ultrasonic, and AI algorithms to handle complex materials and surfaces.

Portable and Wearable Devices: Miniature gauges for on-site quality inspection, leveraging wireless connectivity for real-time data sharing.

AI-Powered Analytics: Machine learning models that predict thickness variations based on process parameters, enabling preemptive adjustments.

In conclusion, film thickness gauges have transcended mere measurement tools to become integral to smart manufacturing. Their ability to deliver precision, real-time insights, and process integration makes them indispensable for industries striving for excellence in an era of ever-rising quality standards.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down