Ensuring the surface quality of industrial products is critical for functionality, aesthetics, and safety across sectors like manufacturing, electronics, automotive, and packaging. Surface defects—such as scratches, cracks, dents, stains, or material inconsistencies—can compromise product performance and lead to costly recalls. Traditional manual inspection, reliant on human visual assessment, suffers from subjectivity, fatigue, and inefficiency, especially for high-speed production lines. Modern industrial applications now leverage advanced technologies to achieve automated, precise, and scalable surface defect detection. This article outlines the key methodologies driving innovation in this field.

1. Machine Vision-Based Detection

Principle: Machine vision systems use high-resolution cameras, lighting systems, and image processing algorithms to analyze product surfaces. Images are captured in real-time, converted into digital signals, and processed to identify anomalies by comparing against reference standards or detecting deviations from normal patterns.

Key Techniques:

Thresholding & Edge Detection: Basic algorithms segment images into regions of interest (ROI) by analyzing pixel intensity differences, useful for detecting obvious defects like scratches or color inconsistencies.

Texture Analysis: Filters (e.g., Gabor filters, Fourier transforms) examine periodic or statistical texture patterns to identify irregularities in surfaces like fabrics, metals, or plastics.

Shape Matching: Geometric features (contours, angles, symmetry) are compared against templates to detect deformations or dimensional errors.

Advantages: Non-contact, high-speed operation (up to 1000+ frames per second), and adaptability to diverse materials.Limitations: Struggles with complex backgrounds, low-contrast defects, or highly reflective surfaces; requires careful calibration of lighting and camera settings.

2. Deep Learning-Powered Approaches

Principle: Deep neural networks, particularly Convolutional Neural Networks (CNNs), excel at learning hierarchical visual features from large datasets, enabling end-to-end defect detection without manual feature engineering.

Popular Models:

Classification Networks (e.g., ResNet, VGG): Classify regions as "defective" or "non-defective" after training on labeled defect images.

Segmentation Models (e.g., U-Net, Mask R-CNN): Localize defects at the pixel level, providing precise coordinates and shapes for complex anomalies like cracks or corrosion.

Anomaly Detection (e.g., Autoencoders, GANs): Train on only defect-free samples to reconstruct normal patterns; significant reconstruction errors indicate defects, ideal for rare defect scenarios where labeled data is scarce.

Advantages: High accuracy (often >99% for common defects), ability to handle unstructured data, and minimal human intervention.Challenges: Requires large annotated datasets (often 10k+ images) for robust training; computational resources demand (GPUs) and potential overfitting to specific defect types.

3. Non-Visual Sensing Techniques

While visual methods dominate, non-visual sensing complements them for specialized applications:

a. Infrared (IR) Thermography

How it works: Detects temperature variations caused by defects (e.g., cracks disrupting heat flow in metals). Useful for hidden subsurface defects or high-temperature environments (e.g., steel manufacturing).

Application: Automotive component inspection, solar panel defect detection.

b. Eddy Current Testing

Principle: Uses electromagnetic induction to detect conductivity changes in conductive materials (metals). Sensitive to surface/subsurface cracks, corrosion, or thickness variations.

Advantage: Non-destructive, works on non-magnetic metals (aluminum, copper), and integrates with robotic arms for complex geometries.

c. Laser Scanning

Method: Projects laser lines onto surfaces and measures deviations in reflected light to create 3D point clouds, identifying dimensional defects (dents, warping) with micron-level precision.

Use Case: Aerospace component inspection, automotive panel quality control.

4. Hybrid Systems: Multimodal Fusion

Combining multiple techniques addresses individual limitations:

Vision + IR: Detects both visual flaws (scratches) and thermal anomalies (weld defects) in pipelines.

Deep Learning + Traditional Vision: Preprocess images with classical algorithms to enhance defect contrast before feeding into CNNs, improving efficiency on noisy datasets.

Edge Computing Integration: Deploy lightweight models on edge devices for real-time inference, reducing latency in high-speed production lines while transmitting data to the cloud for long-term analytics.

5. Industry-Specific Applications

a. Electronics Manufacturing

PCB Inspection: Detects soldering defects, missing components, or trace discontinuities using high-magnification vision systems.

Display Panels: Identifies dead pixels, dust particles, or uneven coatings in LCD/OLED production via automated optical inspection (AOI).

b. Automotive Industry

Sheet Metal Forming: Laser scanners detect surface wrinkles or dents in car body panels; eddy current sensors inspect painted surfaces for hidden corrosion.

Powertrain Components: Ultrasonic testing combined with machine vision ensures defect-free gears and engine parts.

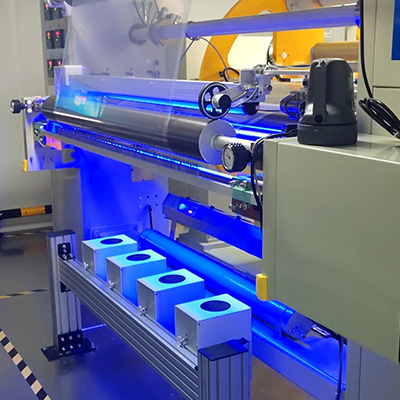

c. Packaging & Printing

Flexible Packaging: Real-time detection of seal defects, ink smudges, or perforation errors in plastic films using line-scan cameras and texture analysis algorithms.

6. Challenges and Future Directions

Data Scarcity: Rare defects lack sufficient training samples; few-shot learning and synthetic data generation (via GANs) are emerging solutions.

Adaptability to New Defects: Systems require retraining for previously unseen anomalies; self-supervised learning models that continuously update from unlabeled data show promise.

Standardization: Lack of universal defect taxonomies complicates cross-industry model reuse; efforts to create shared datasets (e.g., MVTec AD, NEU-DET) are bridging this gap.

Sustainability: Energy-efficient hardware (low-power edge GPUs) and eco-friendly sensing technologies align with global green manufacturing goals.

Surface defect detection has evolved from a manual, error-prone process to an automated, intelligent system critical for Industry 4.0. Machine vision and deep learning lead the charge, offering unprecedented accuracy and scalability, while non-visual techniques and multimodal fusion address niche challenges. As industrial automation advances, the integration of real-time analytics, predictive maintenance, and adaptive learning will further transform defect detection into a proactive quality management tool—ensuring product excellence, reducing waste, and driving operational efficiency in global manufacturing.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down