In today's highly competitive manufacturing sector, product quality is the lifeline of an enterprise. Especially for widely used materials like non-woven fabrics, any minor defect on their surface may affect the performance and aesthetic appeal of the final product. It is precisely against this backdrop that surface defect detection equipment emerged, becoming a key tool for enhancing production efficiency and ensuring product quality. This article will delve into the innovative aspects of this technology and take "non-woven fabric surface defect detection" as an example to demonstrate its unique value.

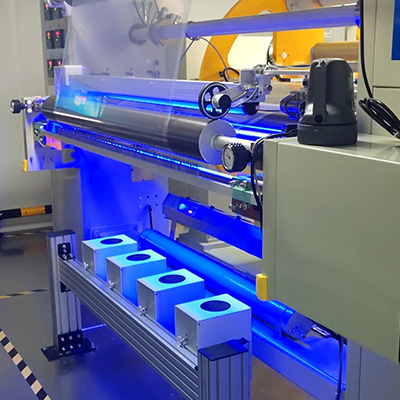

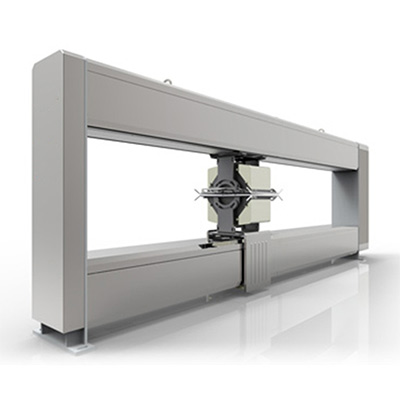

With the advancement of technology, traditional manual visual inspection has become difficult to meet the production demands of high precision and high efficiency. Modern surface defect detection equipment integrates advanced image processing technology, machine learning algorithms and high-speed camera systems, which can capture and analyze the subtle abnormalities of materials in real time on the production line. These systems conduct all-round scans of non-woven fabrics through high-resolution cameras and use deep learning models to quickly identify various defects such as holes, stains, and uneven lines, with an accuracy rate far exceeding human judgment.

Take the non-woven fabric industry as an example. During the production process of this material, it is very easy for randomly distributed small spots or fiber agglomeration to occur. If these problems are not detected and dealt with in time, it will directly lead to a decline in the qualification rate of downstream products. After adopting professional surface defect detection equipment, not only can 24-hour continuous monitoring be achieved, but also defect types can be automatically classified according to preset standards, providing data support for subsequent quality improvement. More importantly, it can immediately feed back the test results to the control system, automatically adjust the production process parameters, thereby effectively reducing the scrap rate and lowering production costs.

In addition to its efficient detection capabilities, this type of equipment also has powerful data processing functions. By collecting and analyzing a large amount of detection data, enterprises can obtain valuable information about the stability of the production process, further optimize the production process, and prevent the occurrence of potential quality problems. For instance, if trend analysis reveals that a specific type of defect frequently occurs within a certain period of time, it can be traced back to problems in raw material supply or a certain process link, and measures can be taken promptly to solve them.

It is worth noting that high-end surface defect detection equipment is often designed with a user-friendly interface that is easy to operate and learn, allowing even non-professionals to quickly get started. Meanwhile, they support remote monitoring and maintenance, enabling technicians to complete equipment debugging and troubleshooting without having to be on-site in person, which greatly improves work efficiency.

Today, with the increasing environmental awareness, reducing waste is also part of corporate social responsibility. Precise surface defect detection helps maximize the utilization of raw materials, reduce resource waste caused by quality issues, and meets the requirements of sustainable development. For non-woven fabric manufacturers that pursue green production, investing in such an intelligent detection system is undoubtedly a wise move towards the future.

In conclusion, surface defect detection equipment is leading the manufacturing industry towards higher quality and greater efficiency with its outstanding performance and broad application prospects. Especially in the quality control of fine materials such as non-woven fabrics, it is not only a guardian of quality but also an enhancer of production efficiency. With the continuous iteration and upgrading of technology, such devices will play an important role in more fields in the future, promoting the transformation and upgrading of the entire industry.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down