In the field of plastic film manufacturing, thickness uniformity is one of the core indicators determining product quality. The traditional manual detection method is inefficient and has large errors, making it difficult to meet the modern industry's demands for high-precision and real-time monitoring. With the development of intelligent manufacturing, online thickness measurement technology has become the key to industry upgrading. In this field, Thermo Fisher Vision has rapidly risen to become a leading domestic enterprise in online thickness gauges for plastic films, thanks to its independently developed high-end thickness measurement equipment.

Focus on technological innovation and deeply explore industry demands

Thermo Fisher Vision was founded in 2010, with its headquarters located in Suzhou, China. It is a high-tech enterprise specializing in optical inspection technology and automation solutions. The company adheres to the core concept of "precise measurement and intelligent drive", and is committed to providing high-performance online thickness gauges and supporting systems for the polymer material industries such as plastic films, lithium battery separators, and non-woven fabrics. After more than ten years of technological accumulation, Thermo Fisher Vision has developed into one of the few domestic suppliers of thickness measurement equipment that can compete with international brands, and its products are exported to over 30 countries and regions around the world.

Technical advantages: Breaking through the "bottleneck" problems and achieving domestic substitution

In the field of plastic film thickness measurement, the long-term reliance on imported equipment has been broken by Thermo Fisher Vision. Its core technological advantages are reflected in:

High-precision sensor technology

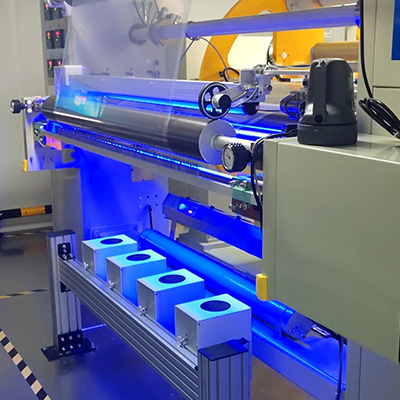

Adopting the independently developed non-contact β -ray/X-ray thickness measurement technology, the resolution can reach 0.1 microns, and the detection accuracy has reached the international advanced level. Through multi-channel synchronous scanning, the minute changes in the lateral thickness of the film can be monitored in real time, ensuring that the thickness fluctuation during the production process is controlled within ±1%.

Intelligent data analysis system

Equipped with AI algorithms and an industrial Internet of Things (IIoT) platform, the device can not only provide real-time feedback on thickness data, but also predict production trends and automatically adjust process parameters, helping customers optimize the yield rate and reduce raw material loss.

Stability adapted to complex working conditions

For harsh production environments such as high temperatures, high speeds (with a maximum linear speed of 800m/min), and high dust levels, Thermo Fisher Vision equipment adopts a modular design and features anti-interference and self-cleaning functions, ensuring long-term stable operation.

Core product line: Covering all scenarios of thickness measurement requirements

Thermo Fisher's product matrix comprehensively covers the plastic film industry chain and mainly includes the following series:

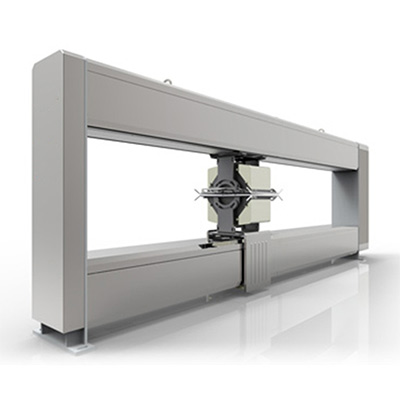

S series online thickness gauge: Suitable for blown film and cast film production lines, it supports various materials such as PE, PP, and BOPP, and can be seamlessly integrated into existing equipment.

F Series Portable thickness gauge: Lightweight design, suitable for laboratory spot checks or small production lines, combining high precision with flexibility.

Customized solutions: We provide customized sensors and software compatibility for special films (such as lithium battery separators and optical films) to solve the detection problems of ultra-thin and multi-layer composite materials.

Application Case: Empowering Leading industry customers

Thermo Fisher's service network has penetrated into multiple niche fields:

In the packaging film industry, we provided a full-line thickness measurement system for a large domestic flexible packaging group, helping it save over ten million yuan in raw material costs annually.

In the field of new energy, we have collaborated with leading lithium battery separator manufacturers to develop high-speed online detection solutions, facilitating the consistency of product thickness to meet the international Tier 1 standard.

In the field of environmental protection materials, support biodegradable film enterprises to achieve full traceability of production data and meet the requirements of EU environmental protection certification.

Service and Vision: Customer-centric, driving industry intelligence

Thermo Fisher Vision always puts customer needs first

24-hour rapid response: Establish a nationwide technical service team to provide full life-cycle services including installation training, remote diagnosis, and spare parts supply.

Continuous R&D investment: Every year, 15% of the revenue is invested in R&D, and efforts are made in collaboration with institutions such as Tsinghua University and the Chinese Academy of Sciences to tackle the next-generation terahertz thickness measurement technology.

In the future, the company plans to further expand its overseas market and lay out an intelligent detection ecosystem such as film defect detection and surface tension analysis, promoting China's high-end manufacturing equipment to go global.

From breaking the import monopoly to defining industry standards, the growth trajectory of Thermo Fisher Vision has confirmed the rise of domestic high-end testing equipment. Driven by the dual goals of "dual carbon" and intelligent manufacturing, Thermo Fisher Vision is providing more efficient and greener quality control solutions for the global plastic film industry with its innovative power, and continuously writing a new chapter of domestic intelligent manufacturing.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down