The pain points of traditional detection

Manual quality inspection is inefficient (only 200-300 items can be inspected per hour) and has a high rate of missed inspections (about 15%). In contrast, traditional machine vision relies on manual rule setting and is difficult to handle complex and variable defect types (such as minor scratches, color differences, abnormal textures, etc.), which seriously restricts production efficiency and product quality.

Deep learning solutions

Core advantages

High-precision recognition: Automatically learns defect features, with a detection accuracy exceeding 99%, and can identify defects as small as 0.01mm² (such as hair-level scratches).

High efficiency and flexibility: Processes 50 to 100 images per second, suitable for high-speed production lines (speed ≥30m/min), and supports over 100 types of defect classification.

Cost reduction: Replacing over 80% of manual quality inspection, a single production line saves more than 500,000 yuan in labor costs annually.

Technical highlights

Customized models can be trained with a small number of samples without complex programming.

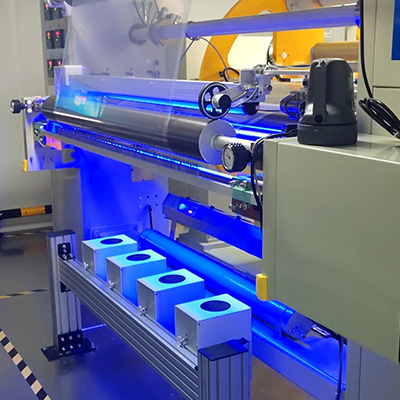

Compatible with multiple industrial scenarios: surface inspection of materials such as metals, plastics, glass, textiles, etc.

Real-time alarm + data visualization for rapid location of process issues.

Typical application scenarios

Electronics industry: Chip solder joint defects, FPC circuit breaks

Automobile manufacturing: Scratches on the body paint surface, dimensional deviations of components

Packaging materials: Film bubbles, label printing defects

New energy: Micro-holes in lithium battery separators, hidden cracks in photovoltaic panels

Case effect

After a certain mobile phone screen factory deployed the system, the missed inspection rate dropped from 12% to 0.5%, the quality inspection efficiency increased by six times, and the annual rework loss was reduced by 8 million yuan.

Why choose deep learning detection?

Quick return: Application can be implemented within 3 to 6 months, with a short investment payback period.

Continuous evolution: The model is constantly optimized as data accumulates, adapting to production line upgrades.

Quality traceability: Automatically generate test reports to facilitate ISO quality management certification.

Deep learning is reshaping the industrial quality inspection model, safeguarding product quality with an "AI eye", helping enterprises reduce costs and increase efficiency, and seizing the high ground of quality competition.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down