With the continuous development of modern electronic manufacturing and precision processing technologies, metal films play a key role in fields such as semiconductors, optical devices, and new energy equipment. However, metal films are prone to micron-level defects such as cracks, voids, and impurities during processing. These defects not only affect the performance of the devices but may also cause serious safety hazards. Therefore, developing high-precision and high-sensitivity surface defect detection technologies for metal films has become an important topic in current scientific research and industrial fields.

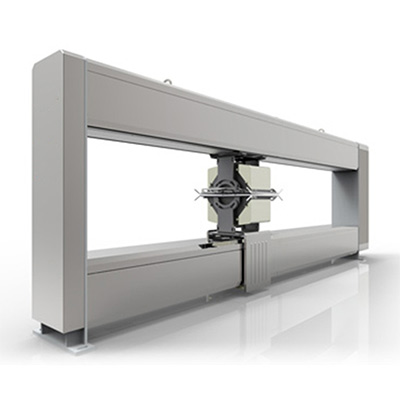

Against this backdrop, Thermo Fisher Vision, as a global leader in optical inspection solutions, has launched a series of innovative technologies suitable for metal film defect detection, leveraging its profound accumulation in optical imaging, spectral analysis and precision measurement. Thermo Fisher's detection system adopts high-resolution optical imaging technology, which can achieve high-precision identification and location of micron-level defects on the surface of metal films, providing strong technical support for industrial inspection.

The core challenges of Metal film defect detection

Defects in metal films usually present at the microscopic scale, such as cracks, holes or impurities at the nanometer or micrometer level. These defects are often hidden on the surface of the film and difficult to observe directly. Although traditional detection methods such as optical microscopes and electron microscopes can provide a certain resolution, they are prone to interference in complex environments and have limitations in detection accuracy and efficiency. Therefore, there is an urgent need for a technical solution that can meet the requirements of high precision, high sensitivity and rapid detection.

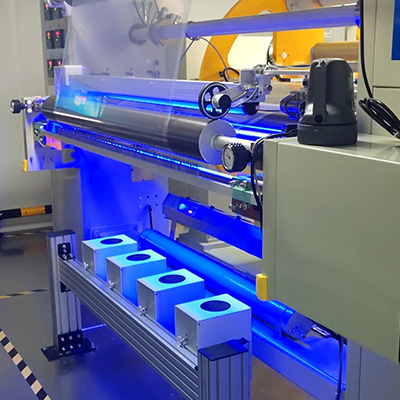

Thermo Fisher's detection system, by combining high-precision optical microscopes with advanced image processing algorithms, achieves precise identification of surface defects in metal films. Its detection process is based on the interference, diffraction and scattering characteristics of light, capable of high-resolution imaging of surface defects, and automatically classifying and analyzing the type, location and size of defects through intelligent algorithms. This technology not only enhances the accuracy of detection but also significantly improves the detection efficiency, providing reliable quality assurance for industrial production.

"Technical Advantages and Application Prospects

Thermo Fisher's detection system has the following significant advantages:

1. ** High-resolution Imaging technology ** : Utilizing an advanced optical system, it achieves high-definition imaging of micron-level defects, ensuring the accuracy of the inspection results.

2. ** Intelligent Analysis Algorithm ** : Based on artificial intelligence and machine learning technologies, the system can automatically identify defect types and provide detailed detection reports, reducing manual intervention.

3. ** Multi-mode detection capability ** : Supports multiple detection modes to meet the detection requirements of metal films of different materials and structures.

4. ** Fast and efficient ** : Compared with traditional detection methods, Thermo Fisher's system can complete large-scale detection in a short time, significantly improving production efficiency.

In practical applications, Thermo Fisher Vision's detection technology has been widely used in semiconductor manufacturing, optical device production, new energy batteries and other fields. For instance, in semiconductor manufacturing, the defect detection of metal films directly affects the performance and lifespan of devices. In the production of optical devices, the detection of defects can ensure the optical quality and stability of the products.

"Future development direction

With the continuous advancement of technology, the defect detection technology for metal films will also keep evolving. In the future, Thermo Fisher Vision will continue to increase its investment in research and development, exploring more advanced detection methods, such as adaptive detection systems based on artificial intelligence, multispectral imaging technology, and nanoscale detection means. In addition, with the advancement of Industry 4.0 and intelligent manufacturing, detection technology will develop towards intelligence, automation and integration, further enhancing the accuracy and efficiency of metal film detection.

In conclusion, the precise detection of micron-level defects on the surface of metal films is a key link in the high-quality development of modern industry. Thermo Fisher Vision, with its advanced technology and innovative solutions, has provided strong support for this field, driving the detection technology to a higher level.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down