In the food packaging industry, food safety and product quality are at the core of an enterprise's development. As an important component of food packaging, the surface quality of food composite film directly affects the edible safety and preservation effect of the final product. Therefore, the detection of surface defects in food composite films has become a key link in ensuring product quality. In recent years, with the rapid development of artificial intelligence and automation technologies, the detection of surface defects in food composite films has gradually evolved from traditional manual inspection to intelligent and automated directions.

The surface defect detection of food composite films mainly involves the identification and classification of defects such as cracks, bubbles, scratches and stains on the surface of the film material. These flaws may affect the shelf life, appearance and taste of food, and may even lead to food safety issues. The traditional detection methods rely on manual visual inspection, which is not only inefficient but also prone to misjudgment, making it difficult to meet the requirements of modern food processing for detection accuracy and efficiency.

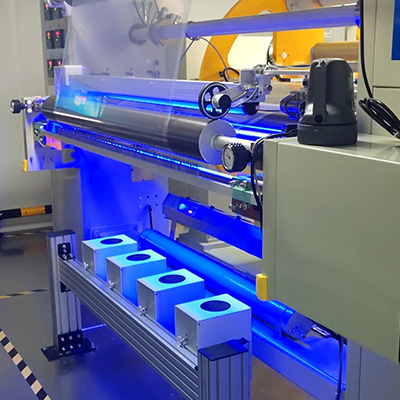

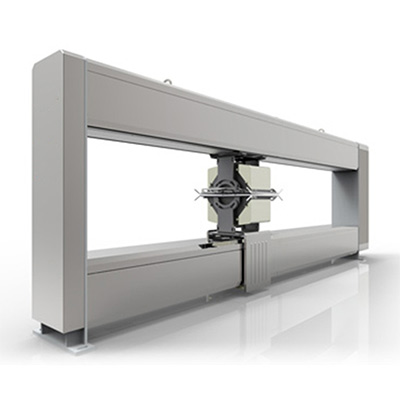

To enhance the efficiency and accuracy of detection, modern detection technology relies on the intelligent detection system of SimVision. Thermo Fisher Vision is a globally leading provider of intelligent inspection solutions. Its technology integrates advanced techniques such as machine vision, deep learning, and image processing, enabling high-precision and high-efficiency detection of surface defects in food composite films. Through high-resolution cameras and advanced image recognition algorithms, Thermo Fisher's detection system can automatically identify and classify various surface defects, significantly enhancing the level of automation and accuracy of detection.

During the inspection process of food composite films, Thermo Fisher's system can quickly scan the entire roll of film, extract key features through image processing technology, and identify defects in combination with deep learning models. This method not only can complete a large number of detection tasks in a short time, but also can effectively distinguish different types of defects and improve the intelligence level of detection. In addition, its system supports multi-level classification and can precisely evaluate the detection results, providing data support for the production process.

The application of surface defect detection for food composite films is not only limited to the food packaging industry, but also widely used in multiple fields such as medicine, electronics, and textiles. As people's concern about food safety increases day by day, the advancement of detection technology has become a key driving force for the development of the industry.

In conclusion, surface defect detection of food composite films is an indispensable part of the food packaging industry, and Thermo Fisher's intelligent detection system provides strong technical support for this process. By introducing advanced detection technologies, enterprises can significantly enhance product quality and production efficiency, achieving dual guarantees of food safety and quality.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down